DIY Small Boat Plans for Under $1000: A Comprehensive Guide

Constructing a small boat on a budget can be a rewarding and achievable project for skilled DIY enthusiasts. This comprehensive guide details the process of designing and building a functional small boat for under $1000, emphasizing careful planning, material selection, and efficient construction techniques.

I. Conceptualization and Design

The initial phase involves defining the boat's purpose, dimensions, and overall design. Careful consideration of these factors is crucial to ensure the final product meets your needs and remains within the budgetary constraints.

A. Defining the Boat's Purpose

The intended use heavily influences the boat's design. Will it be used for fishing, recreational paddling, or simply exploring calm waters? A fishing boat requires features like rod holders and ample storage, while a recreational boat might prioritize stability and comfort. Clearly defining the boat's primary function streamlines the design process.

B. Determining Dimensions and Materials

The boat's dimensions, including length, beam (width), and depth, are determined by its intended use and the available space for construction and storage. Smaller boats are generally easier and cheaper to build. Material selection significantly impacts both cost and durability. Common cost-effective options include plywood (marine-grade is recommended for extended lifespan), fiberglass, and even repurposed materials like plastic barrels (for very basic designs). Consider the weight and strength characteristics of each material in relation to the boat's intended use and your construction skills.

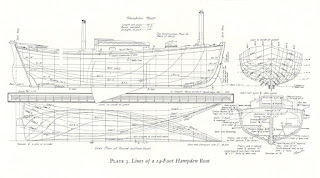

C. Choosing a Boat Design

Numerous boat plans are readily available online and in books, ranging from simple designs like canoes and kayaks to more complex designs like small rowboats or punts. Selecting a plan that matches your skill level and budget is paramount. Beginners should opt for simpler designs with clear instructions and readily available materials. Free plans can be found online, but thoroughly vet their source and reviews before proceeding. Simple designs often translate to lower material costs and easier construction.

II. Material Acquisition and Preparation

Once the design is finalized, the next step is sourcing the necessary materials. Careful planning and comparison shopping can significantly reduce costs.

A. Sourcing Materials

Utilize a combination of new and salvaged materials to minimize expenses. Marine-grade plywood is a preferred choice for its water resistance. However, if the budget is extremely tight, consider pressure-treated lumber (ensure it's adequately sealed to prevent rot) or reclaimed wood, keeping in mind the reduced lifespan. Hardware stores, lumber yards, and online marketplaces offer varying price points. Comparative shopping and negotiating prices can yield significant savings.

B. Pre-Construction Preparation

Before commencing construction, thoroughly prepare all materials. This includes cutting plywood to the dimensions specified in the plans, ensuring proper sealing of any wood with marine-grade varnish or epoxy resin to enhance water resistance and longevity. Hardware should be chosen carefully – opting for stainless steel or galvanized options that are resistant to corrosion. Pre-drilling holes for screws and bolts prevents material splitting and ensures a neat finish.

III. Boat Construction

The construction phase requires meticulous attention to detail and adherence to the chosen plans. Patience and accuracy are essential for a structurally sound and watertight vessel.

A. Framework Construction

Most small boat plans involve constructing a framework, typically using wood, which provides the skeleton for the boat's hull. Follow the plans meticulously, ensuring the framework is square and true. Use strong adhesives and appropriate fasteners (screws and/or nails) for secure joints. Proper bracing is crucial to maintain the framework's structural integrity during the subsequent steps.

B. Hull Construction

Once the framework is completed, the hull is constructed by attaching the chosen material (plywood, fiberglass, etc.) to the framework. Pay attention to the sequence of attaching panels to ensure a smooth, watertight hull. Use appropriate adhesives and fasteners and ensure panels are securely attached and aligned. Caulking any gaps and seams is critical to prevent leaks. This step often involves the application of fiberglass cloth and resin for added strength and waterproofing (if using plywood).

C. Finishing Touches

After the hull is complete, add any necessary features such as seats, oarlocks, storage compartments, and a protective coating. Sand any rough surfaces smooth and apply several coats of marine-grade paint or varnish to provide protection against the elements and enhance the boat's appearance. This stage also includes installing any necessary hardware, ensuring that everything is securely fastened and correctly aligned.

IV. Testing and Refinement

Before launching the boat, it's crucial to conduct thorough testing to identify and rectify any potential issues.

A. Leak Testing

Thoroughly test for leaks by filling the boat with water and inspecting for any seepage. Address any leaks immediately by caulking or patching as needed. This is a critical step to prevent sinking or water damage.

B. Stability Testing

Assess the boat's stability by gently shifting weight around the boat. It should maintain equilibrium and not feel unstable. Addressing any stability concerns may require adding ballast or re-evaluating the hull design.

C. Initial Launch

Conduct an initial launch in calm waters, checking for any unexpected issues with buoyancy, handling, or stability. Make any necessary adjustments or modifications based on your observations during the test run.

V. Cost Optimization Strategies

Staying within a $1000 budget requires careful planning and resourceful strategies.

Strategies for Cost Reduction:

- Utilize free or low-cost plans: Numerous free boat plans are available online, significantly reducing initial design costs.

- Source materials from multiple vendors: Compare prices at different hardware stores and lumber yards to find the best deals on materials.

- Repurpose or recycle materials: Consider using reclaimed wood, salvaged parts, or recycled containers where appropriate.

- Borrow or rent tools: Avoid the high cost of purchasing specialized tools by borrowing them from friends or renting them from tool rental shops.

- Prioritize essential features: Focus on the core functionality and avoid unnecessary features to reduce material and labor costs.

- Seek assistance from experienced boat builders: Seeking advice or assistance from experienced individuals can help avoid costly mistakes and optimize construction efficiency.

Constructing a small boat on a budget requires careful planning, resourcefulness, and a commitment to the project. By following these guidelines, you can significantly enhance your chances of successfully building a functional and affordable boat, while simultaneously enjoying a rewarding and enriching DIY experience.